- Milk microfiltration technology

- High-temperature impulse technology (indirect heating)

- Technology of steam processing of milk (direct heating)

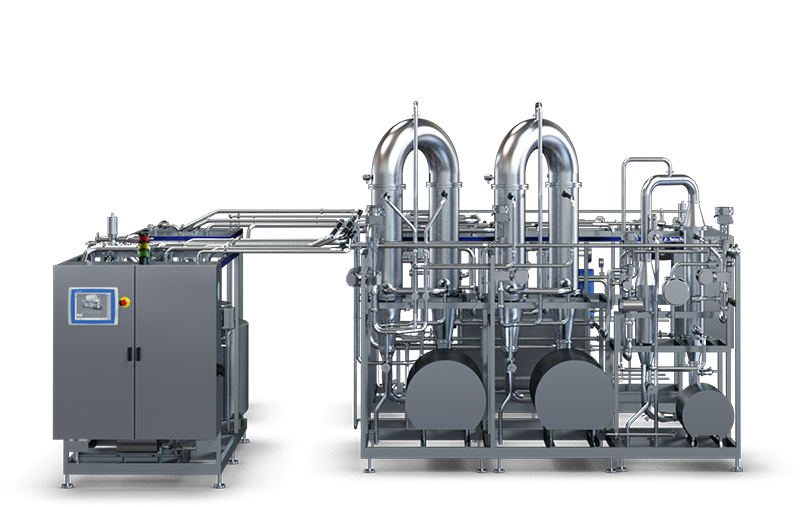

Microfiltration is the most advanced milk purification technology currently available in the world.

In many countries of the world, this technology has been widely used for a long time for the production of high-quality milk. Loostdorf is the first company to implement this technology in Ukraine.

Microfiltration removes not only bacteria, but also their spores from milk. Milk is purified using modern ceramic membranes. Such efficiency cannot be achieved by any other methods of milk purification.

After cleaning, the milk is pasteurized in the most careful way at the lowest possible temperature - 72°C, in order to preserve its natural taste and natural values. Thanks to purification and gentle pasteurization, milk has different taste (delicate, creamier, without side tastes).

High-temperature impulse technology: The essence of the high-temperature impulse technology (UHT) is that within 2-4 seconds the raw milk is subjected to a thermal impulse with a temperature of 137°C, after which it is just as quickly cooled to 25°C. This modern technology allows to destroy all pathogenic bacteria and preserve the natural value of milk. Thanks to careful heat treatment and packaging in a protected environment in aseptic packaging, UHT dairy products can be stored in closed packaging for a long period.

The technology assumes that steam is injected into milk under high pressure (4 bar), instantly heating it to 140°C. Then, after a few seconds, the milk is cooled to 20°C without contact with air and light. This allows to very carefully clean the milk from bacteria, to maximize its natural values and delicious taste, and at the same time to avoid the taste of boiling. Thanks to careful heat treatment and sterile environment aseptic packaging, UHT dairy products can be stored in closed packaging for a long period.